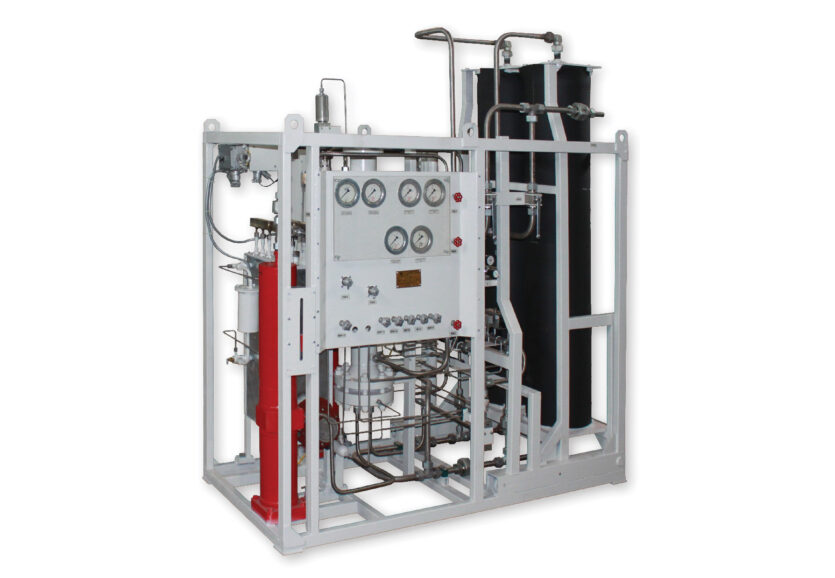

Gas Preparation, Purification, and Drying Unit

SENSI LLC manufactures efficient gas drying systems that can be used for the preparation of natural and associated petroleum gas. These systems include low and high-pressure dryers that effectively remove moisture, preventing corrosion of equipment and pipelines.

Key Features:

- Versatility: The dryers can be installed at either the inlet or outlet of compressor stations.

- Efficiency: Utilizes heated low-pressure gas for adsorbent regeneration, ensuring high drying efficiency.

- Control and Management: Equipped with moisture meters and control panels, allowing for manual, semi-automatic, or automatic operation modes.

| Parameter | Low-pressure drying | High-pressure drying |

|---|---|---|

| Maximum pressure in adsorbers, bar | 16 | 250 |

| Volume of one adsorber, m3 | 1,0 | 0,1 |

| Maximum temperature of liquid in electric heater, °С | 160 | 160 |

| Maximum temperature of regeneration gas, °С | 120 | 120 |

| Moisture content after drying, not more than , g/nm3 | 0,009 | 0,009 |

| Volume of polymethylsaloxane liquid to be filled into the electric heater, liters | 100 | 90 |

| Power used for regeneration, not more, kW | 20 | 10 |

| Throughput capacity, not more, nm3/h | 3000 | 2000 |

| Consumption of gas taken for regeneration, not more, % | – | 5 |